Self Cleaning Screen Mesh, is my company according to customer needs, on the basis of the original vibrating screen, research, and development of the comprehensive performance of a new generation of products. It uses air springs, push-wave screen, screen fast locking device and the overall suspension lifting frame, which can effectively overcome or avoid the shortcomings and deficiencies of the existing domestic and foreign Shaker exists to improve

Self Cleaning Screen Mesh drilling fluid handling capacity, operation and maintenance more convenient.

Second, the main advantages

1, Self Cleaning Screen Mesh fast locking device, the handle is rotated 90°to lock or loosen, disassembly screen operation is fast and convenient.

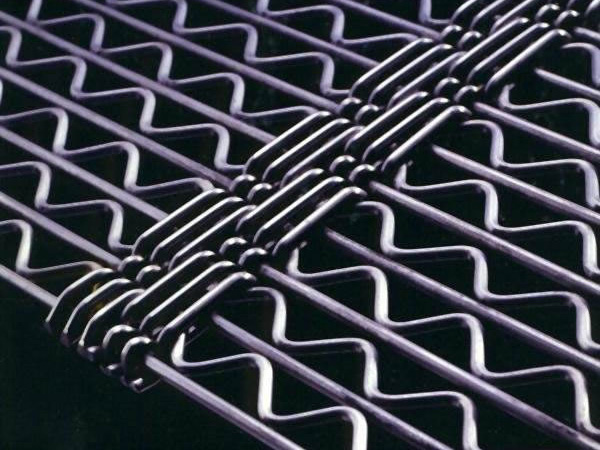

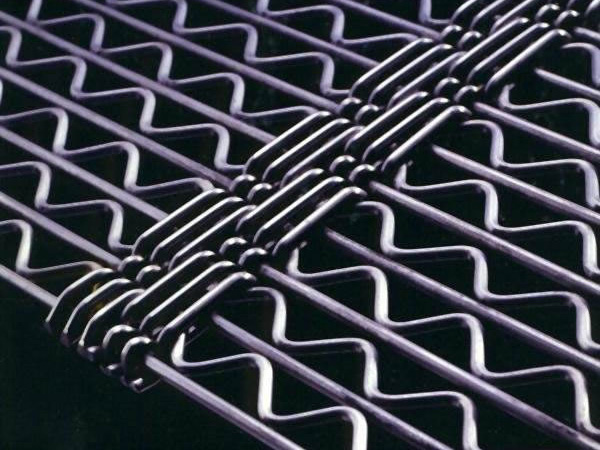

2, the use of six shaped wave screen, anti-deformation strength, low adhesion, self-cleaning effect, the contact area increased by 60%, handling capacity, the use of higher number, and long life, low cost.

3, the first domestic gas spring design in the drilling fluid Shaker, sieve box larger amplitude, vibration is more stable, the best vibration isolation, thereby improving the life and processing capacity of the sieve box.

4, the first use of super-rigid concave arc type screen box, with a screen box to prevent retention of mud and prevent both sides of the self-cleaning properties of running pulp splash, extending the life of the shaker and screen.

5, fully enclosed folding stainless steel block pulp board, beautiful and light, corrosion resistance, convenient operation.

6, an integral quick lift adjustment device, hydraulic drive, quick and light operation, good stability.

7,

Self Cleaning Screen Mesh with super rigid structure design, and a large number of stainless steel parts, extended service life.