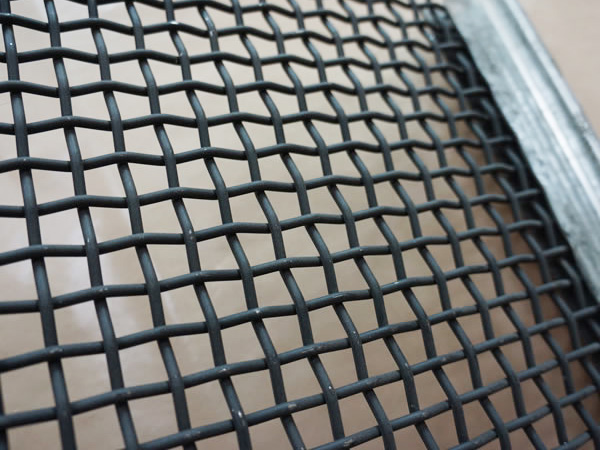

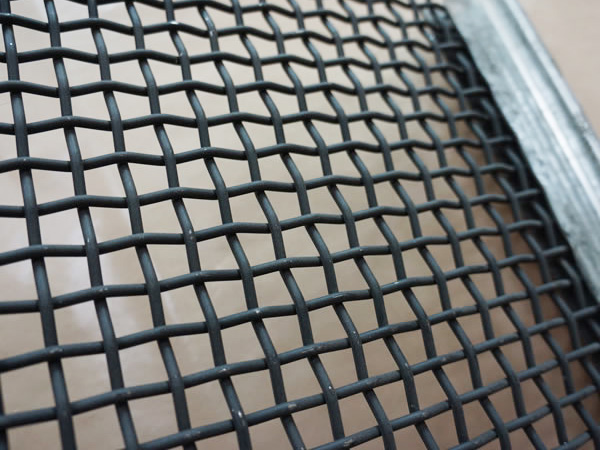

It is often seen that the

Vibrating Screen Mesh for quartz sand screening is usually a straight line Vibrating Screen Mesh or a rotary vibrating screen. I recommend these two kinds of Vibrating Screen Mesh, and briefly explain their differences and how to rationalize screening.

Quartz Sand Using Rotary Vibrating Screen

Screening quartz sand by the rotary vibrating screen is very mature. The basic principle of rotary vibrating screen is to transform the rotating motion of the motor into three-dimensional motion of horizontal, vertical and inclined by using the weights installed on the upper and lower axles of the motor (unbalanced weights). This motion is then transmitted to the screen surface to make the material move in an extended involute on the screen surface. Therefore, this series of

Vibrating Screen Mesh is called rotary Vibrating Screen. Screen Mesh. Because of its high efficiency, simple operation, continuous operation, and high screening accuracy, it is often used in quartz sand screening. If the number of quartz sand is large, the processing capacity will be affected.

Quartz sand is straight-line Vibrating Screen Mesh

Linear Vibrating Screen Mesh (Linear Screen) is a new type of screening equipment, which is widely used in mining, coal, smelting, building materials, refractories, light industry, chemical industry, and other industries. Linear Vibrating Screen Mesh (Linear Screen) has the advantages of stability, reliability, low consumption, low noise, long service life, stable vibration mode, and high screening efficiency. It has the characteristics of low energy consumption, high efficiency, simple structure, easy maintenance and no dust spill in a fully enclosed structure. The main feature is that the processing capacity is large, but the screening accuracy is lower than that of the rotary vibrating screen.

When screening quartz sand, we usually use these two kinds of

Vibrating Screen Mesh for screening. Linear Vibrating Screen Mesh is responsible for coarse screening and a rotary vibrating screen is responsible for fine screening, so screening quartz sand is more reasonable.